The year 2022 is the year of the 20th Party Congress and the opening year of a new journey to build a modern socialist country in all aspects and march towards the second century goal. The report of the 20th Party Congress set the strategic goal of fully building a socialist modern country and advancing the great rejuvenation of the Chinese nation with Chinese-style modernization, drawing a grand blueprint for socialism with Chinese characteristics in the new era. In the same year, the General Office of the State Council issued the “Fourteenth Five-Year Plan” for the development of modern logistics, focusing precisely on the key directions of modern logistics development, which bring new opportunities and challenges to the development of the pallet industry.

Although China’s logistics industry in 2022 has endured the impact of the epidemic, the lack of demand and rising costs and other multiple pressures, but the overall still achieve smooth operation. Also due to the impact of the epidemic, the annual output of the pallet industry decreased slightly compared to 2021, but with the liberalization of domestic and foreign epidemic control policies, the significant breakthrough in international cooperation on pallets represented by the “Belt and Road” pallet sharing initiative (BRAPS), the “14th Five-Year Plan Modern Logistics Development Plan” for the development of pallet recycling system construction guidelines, green low-carbon high-quality development of the continued promotion, enterprise cost control for automation, intelligent equipment demand is growing, etc., so that the pallet companies are confident about the development prospects of the pallet market in 2023.

- Review of China Pallet Market Development in 2022

01

Pallet market size growth slowed down

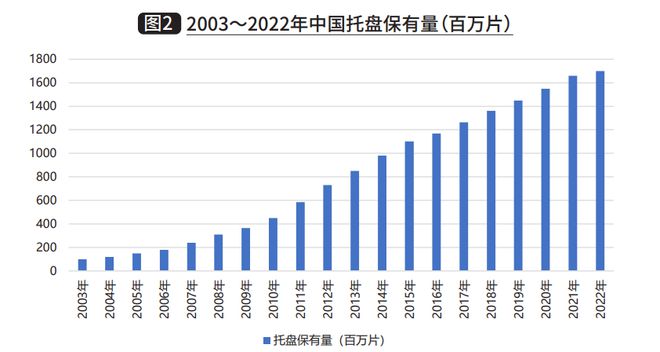

In 2022, due to the impact of the epidemic, the rising cost of raw materials and the lack of customer demand, pallet manufacturers strived to overcome the adverse impact of the epidemic, concentrated their efforts, bucked the trend and made every effort to ensure the normal production and operation of enterprises. In 2022, China’s pallet pool totaled more than 37.5 million pieces, an increase of 3.5 million pieces compared with 2021, an increase of 10.29%. The occupancy rate of wooden pallets decreases year by year, the occupancy rate of plastic pallets increases year by year, and the total occupancy rate of wooden pallets and plastic pallets is above 90%.

02

Industry policies and standards work to clarify the direction of development

(1) Industry Policies

In March 2022, the Central Committee of the Communist Party of China and the State Council issued the Opinions on Accelerating the Construction of a Unified National Market, which pointed out in the section of “Promoting the High Standard of Market Facility Connectivity” that the construction of modern circulation network should be built, including promoting the construction of national logistics hub network, vigorously developing multimodal transportation, and promoting the standardized pallet with board transportation mode.

In September 2022, the General Office of the State Council issued “on further optimizing the business environment to reduce the institutional transaction costs of market entities”, in the “further standardization of enterprise-related fees to promote the reduction of the operating burden of market entities” section, it is pointed out to promote the reduction of logistics service charges, including clear railroads, highways, waterways, aviation, etc. Transport links of the port logistics operation time frame and process, accelerate the promotion of bulk goods and containers in long-distance transport “public to rail” “public to water” and other multimodal transport reform, promote the standardization of transport means of delivery and related documents, in order to ensure the safety of the premise of standardization. Promote the establishment of containers, pallets and other standardized loading apparatus recycling system.

In December 2022, the General Office of the State Council issued the “Fourteenth Five-Year Plan” for the development of modern logistics, in the “promote the development of green logistics” section pointed out that we should further promote energy conservation and emission reduction in logistics, including strengthening the research and development of new green logistics technologies and equipment Application, promote the use of recycling packaging, reduce excessive packaging and secondary packaging, promote packaging reduction, reuse; accelerate the promotion and application of standardized logistics crates, and promote the construction of pallet recycling system.

(2) standard work

In the “Fourteenth Five-Year Plan” modern logistics development plan, column 11 [logistics standardization to promote the project], pointed out that the development of modern logistics standardization development plan, improve the modern logistics standards system. Improve packaging, pallets, crates and other standards, strengthen the standard pallet-based unitary logistics system series of standards and revisions, accelerate the transport means, transport equipment, facilities system and other standard docking and system operation, improve the efficiency of the whole society logistics operation.

In 2022, China Federation of Logistics and Purchasing Pallet Committee (“CFLP Pallet Committee”) and National Logistics Standardization Technical Committee Pallet Sub-Technical Committee officially launched the “Flat Pallet Main Dimensions and Tolerances” (20220568-T-602) and “Pallet Terminology” (20220571-T-602). (20220568-T-602) and “Pallet Terminology” (20220571-T-602), the revision of two national standards of pallet foundation. The two national standards are the most important basic standards in the pallet standard system and play a cornerstone role for other pallet standards, which are widely concerned by the industry and referenced by many national standards, industry standards and local standards. The revision of the two national standards has positive significance for guiding and regulating the benign coordination and high-quality development of the pallet and logistics industry.

The main dimensions and tolerances of flat pallets (20220568-T-602), when revised, are in line with the new development trend of “One Belt and One Road” and the international situation and new changes, and strengthen the docking with European pallet standards, which is conducive to the mutual recognition and sharing of pallets between China and Europe and the “One Belt and One Road” development. “development. At the same time, it also strengthens the coordination and matching between packaging, forklift, freight vehicles and other logistics equipment, fully considers the matching relationship between pallet size and packaging module, vehicles, and realizes the development of mechanization, automatic loading and unloading, warehousing, transportation and distribution of logistics process and transportation with plates, and changes the name of the standard, with the purpose of expanding the application scope of pallets in the original national standard, applicable to all aspects of logistics The flat pallets used in operations.

The revision of the Pallet Terminology (20220571-T-602), which is equivalent to ISO 445:2013 Pallets for materials handling-Vocabulary, is consistent with the latest version of the international standard, realizes the standardization of terminology, uses the means of standardization and strengthens the pallet industry through the strict definition of concepts standardization of internal communication and external communication, reduce technical barriers to trade, meet the needs of international development, better promote trade exchanges and technical cooperation, and promote the standardization and normative development of China’s pallet industry.

In 2022, the “wood flat pallet General Technical Requirements” (GB/T 31148-2022) national standards, as well as “molded flat pallet plant fiber class” (WB/T 1125-2022), “plastic box pallet” (WB/T 1126-2022), “box, column pallet” (WB/T 1127-2022) and “combined plastic pallet” ( WB/T 1128-2022) four logistics industry standards, and “quality classification and “leader” evaluation requirements flat pallet” (T/CFLP 0038-2022, T/CSTE 0112-2022) and “quality classification and “leader The two group standards “Pallet Rental Service” (T/CFLP 0039-2022, T/CSTE 0113-2022) are officially released.

(3) Enterprise standard “leader”

In 2022, the tray committee of CFLP organized the declaration of enterprise standard “frontrunner”. Based on self-declaration of service standards, innovation as the driving force and market-driven, the “leader” of enterprise standards encourages pallet production and leasing service enterprises to play the role of enterprise standards to lead the development of the industry and improve product quality and service quality.

Shenzhen Prato, Nanjing Lan Yu Da, Wuxi Qiancheng, Jiangsu Zhonghe, Tianjin Xinchuang and Jushi Group six pallet production and leasing service enterprise standards won the 2022 enterprise standards “leader”, by the “enterprise standards leader management information platform” officially The six pallet production and leasing service enterprise standards declared in 2022 were all awarded the “leader” in the pallet industry. The six pallets manufacturing and leasing service enterprise standards declared in 2022 all won the “leader” in the pallet industry.

03

A new chapter of international pallet exchange and pallet recycling

Since 2020, the pallet committee of FIC and the European Pallet Association (EPAL) jointly put forward the initiative of “Belt and Road” Pallet Sharing Action (BRAPS), which has received wide attention from the pallet industry. In October, the first Belt and Road Pallet Sharing Action (BRAPS) meeting was held in Guangzhou. This conference is the first important event for domestic and foreign audiences since the establishment of BRAPS, with the theme of “Green, Cooperation, Sharing and Standard”, and jointly exchanged and discussed the new changes of China-Europe pallet industry and the construction of global pallet recycling system under the new situation. Through BRAPS, it will not only help to promote the cooperation between CFL and EPAL and the integration and development of basic logistics standards between China and Europe, but also drive the standardization, networking and sharing of pallets in countries and regions along the “Belt and Road”, promote the development of a broader international pallet market, so as to establish a global open pallet sharing platform. The international pallet sharing platform and the international cross-border pallet recycling system will play a positive role in promoting the high-quality construction of “one belt and one road”, “one belt and one road” economic and trade cooperation and the high-quality development of supply chain globalization.

In 2022, pallet operating companies such as LUCA China, Tibbo, Plato, Shanghai Le Orange and Little Ant Pallet have accelerated the expansion of their respective pallet pool scale and operation network to enhance their service capacity; constantly updated the types of products in the pallet pool to adapt to the synergistic development of multiple industries; launched value-added services with special features, actively promoted the transportation of pallets, improved efficiency, effectively promoted the synergistic development of industrial chain and supply chain. Accelerate the construction of pallet recycling ecosystem and create more sustainable development value for the industry.

Foreign pallet leasing companies have also been carrying out related business in China. The Korea Logistics Group (LogisALL) is an international high-end logistics enterprise with unified logistics as its core. Ltd. is a wholly-owned company invested by LogisALL in Shanghai, actively promoting the recycling of RRPP pallets; Japan Pallet Rental (JPR) is the largest pallet rental supplier in Japan, operating in the Chinese market for many years and maintaining a good relationship with Shenzhen Shun Hang Tong Supply Chain Logistics Co.

04

The price of raw materials for pallets continues to be at a high level

Since the epidemic, the price of imported raw materials for pallets was once high due to the impact of a poor supply chain, but also often in short supply. These uncertainties and instability factors bring great pressure to the development of wood packaging manufacturers and industry, prompting many wood packaging manufacturers and operators to switch to the use of stable supply, moderate price, performance in line with national standards required for domestic wood. China Federation of Material Pallet Committee also continues to strengthen the pallet industry supply chain construction, service network to the upstream extension, do a good job of raw material suppliers and wood packaging enterprises between the upstream and downstream docking work to promote the high-quality development of the pallet industry.

(1) Imported raw material prices

Due to the impact of the domestic epidemic and supply chain is not smooth, 2022 pallet imported raw materials (plates, logs) prices are still at a high level. Affected by the domestic epidemic in the first half of the year, Danish spruce, Canadian hemlock, Russian camphor pine / larch plates 1 to June the overall price of imported plates is high, the second half of the year with the gradual liberalization of the epidemic control and orderly recovery of logistics, July to December the price of imported plates began to decline as a whole, the price in December is generally lower than the price in January. Imported log prices are also lower than the second half of the first half.

(2) domestic sawn timber prices

2022 pallet industry domestic sawn timber (pallet material) prices also remained high, with a slight overall decline. First quarter prices fell slightly, two, three, four quarters due to the impact of the epidemic, prices rose slightly, but the overall price fluctuations throughout the year, December prices fell 1.25% compared to January, compared to the lowest price in 2020 rose 35.04%. 2022 January to September prices are higher than the same period in 2021 prices, October prices and the same period in 2021 prices are basically the same, November ~ December prices are slightly lower than the prices of the same period in 2021.

05

Digital empowerment of high-quality development of the pallet industry

The “Fourteenth Five-Year Plan” modern logistics development plan pointed out that we should improve the modern logistics service system, accelerate the digital transformation of transportation, warehousing, distribution, distribution processing, packaging, loading and unloading, wisdom upgrading and service innovation; to strengthen the digital logistics technology empowerment, the use of modern information technology to promote the logistics elements online data, the development of diverse application scenarios, the realization of logistics resources. Develop diversified application scenarios to realize online and offline linkage of logistics resources. Pallets as the most basic assembly apparatus in the logistics system, digital transformation is an inevitable trend. In the development of recent years, many pallet enterprises are riding on the wave of technology to achieve digital transformation and upgrading.

LUCA empowers the total belt plate transportation service with digitalization, and creates a one-stop digital service platform specifically for the total belt plate transportation scenario, which is user-centered. The platform connects upstream and downstream to help customers improve pallet flow management efficiency, enhance transaction transparency and help enterprises optimize smart supply chain decisions.

With pallet digitalization innovation, Tibbo helps customers build a smart supply chain. The innovative development of pallet coding, pallet information management and smart pallets can improve the efficiency of end-to-end visualization and management of the supply chain, enhance internal digital decision-making capabilities, and achieve accurate placement.

In order to better utilize intelligent logistics to solve the logistics industry problems, Prato insists on digital technology as the basis, integrates through online and offline tandem, continuously implements product and service innovation, adds additional value-added services to products, comprehensively upgrades services for different customer needs, and launches digital services such as Prato E Enjoy, Prato Cloud Warehouse, Prato Cloud Signature, Prato Electronic Signature, etc., so as to realize the upgrade of logistics industry and reduce costs and increase efficiency. We are committed to creating a better supply chain solution and using the convenience of the Internet to guarantee the double improvement of logistics transportation efficiency and safety.

China Pack IOT applies IOT technology to realize the visualization and real-time management of packaging apparatus for supply chain participants. Through software and hardware integration solutions, based on the artificial intelligence AI module installed on the circular packaging, to achieve hourly full process of unmanned data collection, independent reporting to the cloud platform, circular packaging boxes in the supply chain of the whole process of electronic data flow, but also to effectively prevent the tray management difficult, lost, occupied, stagnant and other phenomena, reduce labor costs, empowering packaging new data value.

Little ant tray digital empowerment, no manual inventory, inventory, through the smart chip installed in the tray, can provide the entire data, even if the tray is lost can also be easily traced.

06

Deeply promote the concept of green low-carbon sustainable development

Pallet companies are taking active actions to deeply practice the green and low-carbon development concept and fully integrate the “double carbon” target into their corporate development planning.

LUCA China has updated its sustainable development strategy, based on the United Nations Sustainable Development Goals and the ten principles of the United Nations International Compact, and formulated the three sustainable strategic objectives of “low-carbon recycling, win-win ecology and social responsibility”. Realize green supply chain.

L’Orange was certified by CQC, and the use of L’Orange cloud tray can effectively reduce the carbon footprint, and also launched a new brand “Yelolife L’Orange New Life”, which is a brand-new segment established by L’Orange based on zero-carbon packaging, dedicated to the recycling of waste plastic packaging, the research and development of recycled materials and the design and production of packaging products. L’Orange establishes a closed-loop system for the whole life cycle of plastics, from the use of virgin plastics, the recycling of waste packaging products, the manufacture of recycled plastics and the production of recycled plastic packaging, to create a perfect plastic circular economy system, to eliminate the flow of plastic products into the natural environment causing pollution, to protect the ecology of the earth and to promote green sustainable development.

FSC certification and PEFC certification are highly recognized in the current market and are global forest certification systems supported by non-governmental environmental organizations and trade organizations. In recent years, the demand for FSC and PEFC certification for wood packaging has surged, and more and more wood packaging companies, represented by LuKai and JiBao, choose to use FSC or PEFC certified sustainable raw materials, which can effectively achieve carbon emission reduction while enhancing corporate social responsibility.

07

New material pallet products continue to innovate

Traditional pallets are mainly wood and plastic pallets, and some paper pallets, aluminum pallets, metal pallets, etc. As the price of wood climbs high, low-carbon environmental protection and other factors, the development and application of new material pallets are developing rapidly.

Beijing TANAKE can effectively solve the problems of aging and discoloration of plastic pallets, reduce the weight of pallets by 20%, and improve the durability, service life and cycle times of pallets in recycling, which can not only reduce the cost for enterprises but also take into account environmental protection.

The bamboo wood composite board produced by CIMC is designed and developed based on the application requirements of traditional container flooring, with outstanding features such as high density, high strength, waterproof and moisture-proof, good overall performance and reliable quality. The bamboo material is green, cost-effective and plastic. The bamboo-wood composite pallet designed and developed based on the self-manufactured high-strength bamboo-wood composite material has the advantages of being strong and durable, cost-effective and widely applicable; the moulding production process can keep the overall performance of the pallet stable and consistent, with strong impact resistance and fumigation-free hot pressing; compared with the solid wood pallet, the pallet products with the same performance requirements can be produced with smaller tolerance, material Compared with solid wood pallets, the production of the same performance requirements of the pallet products, tolerance is smaller, material consumption can be saved 30%, the weight is reduced by 10%, both to improve product quality, but also to reduce costs for enterprises.

Inner Mongolia JiaYunTong to industrial solid waste as raw materials, and constantly upgrade the raw materials and process, the production of pallet products can effectively reduce the amount of industrial solid waste and old plastic stockpiles, wood natural resources mining and the use of new plastic raw materials, compared with the traditional pallet, the product weight can be reduced by about 20%, 30% performance improvement, and can save about 15% of the cost.

Henan Ming magnesium technology relying on Jilin University School of Materials Science and Engineering, set up a research center and R & D base to solve the problem of poor plasticity, poor corrosion resistance, poor fatigue of magnesium alloy, the development and production of new magnesium alloy self-demolition logistics tray, unique design, reasonable structure, easy loading and unloading operations.

In addition, Guangdong Dazhong New Materials uses modified materials as raw materials to produce plastic pallets, which can be recovered and recycled, in line with the trend of “carbon neutrality”. Hebei Jujiu uses new composite materials to produce pallets with light quality, high strength, low temperature resistance, wide range of application, and can be disassembled, easy to clean, and can be customized. Wuhu Asia Pacific General uses waste agricultural film and waste plastic from municipal waste sorting as raw materials to develop new energy-saving and environmentally friendly products with revolutionary alternative trend of wood-plastic molded pallets.

08

Intelligent equipment and services to promote the pallet industry to a new level

Foreign pallet manufacturers use automation equipment earlier, wooden pallet automation equipment is mainly based on hydraulic pallet production line, the representative enterprises are Spain’s Cabe (CAPE), Italy’s Delta (DELTA) and Storti (STORTI), in 2011, Tianjin Xinchuang introduced the first hydraulic pallet production line, opened the wave of China’s pallet automation production equipment use and research and development .

In recent years, with the high-quality development of the pallet industry, the vigorous promotion of recycling, the increase in the standardization of pallet products, the continuous rise in labor costs and the high requirements of customers for product delivery speed and quality, the production method of pallet enterprises has changed from traditional manual production to automated production, and more and more enterprises choose to use automated production equipment and continuously optimize the layout of workshop facilities. By increasing investment in research and development, equipment manufacturers continue to launch new products and carry out technological updates and iterations, not only to serve domestic pallet manufacturers, but also to increase overseas business layout and promote “Made in China” to the world. For example, B-PLT logistics pallet special machine series developed by Bochuang based on two-platen intelligent injection molding machine is suitable for full-size plastic pallet injection scenarios in the market, stable and durable, with electric melting glue, high efficiency and energy saving at the same time; it has established a deep cooperation and resource sharing chain with leading enterprises in the industry, and can provide customers with automatic assembly line design for injection pallets or intelligent and informative pallet injection factory solutions.

Terry machine from the preliminary intelligent planning (multi-dimensional program customization), to intelligent production (improve the production efficiency of pallet injection molding), and then intelligent management (production efficiency lean management), truly achieve the management of the whole life cycle of the product. As a representative of domestic wooden pallet automation equipment manufacturer, Qingdao Safan’s product type not only covers pneumatic and hydraulic pallet nailing production line, but also is actively innovating and developing wood finishing equipment, conveying lines, panel machines and other automated processing equipment.

With the birth of millions of recycle share pallets every year, recycle share pallets can be repaired to extend the life cycle and service life of the pallets after completing one use, instead of replacing them with new ones. LUCA’s Jiaxing Super Operation Center, China’s first large scale automated circular carrier operation and service center, has an intensive and large-scale pallet efficient maintenance system, opening a new chapter of automated pallet maintenance and sorting.

09

Cross-border integration and capital assistance to jointly build the pallet industry ecosystem

With the acceleration of global economic integration, enterprises need to be invincible in the increasingly fierce competition and need to optimize resource allocation through integration to improve efficiency, reduce costs, expand market share and strengthen core competitiveness of enterprises.

In 2022, LUCA Group and Blumberg Group officially announced that they will merge LUCA and Tibbo’s logistics carrier recycling business in Mainland China and Hong Kong. The merger of LUCA Greater China and Tibbo China will make it the largest pallet and car crate recycling service provider in Greater China. With significant strengths in Greater China, the combined business will benefit from greater scale and customer reach, thus enhancing customer service capabilities in Greater China and accelerating the value of pallets and car crates. The joint venture will give full play to the scale effect and synergy to accelerate the transformation of China’s pallet market from a static leasing model to a dynamic flow model, in order to help supply chain optimization and innovation and sustainable development.

Zhenjiang Guolin Eco-Industrial City belongs to Zhonglin Group. Xinminzhou Port, as the largest wood processing transit port in China, strives to build a full supply chain system for wood industrialization by virtue of its geographical location, port, land, logistics and raw material sources, with wood pallet and wood packaging production as one of the four major industrial clusters in the future. Zhonglin Carriers, which also belongs to Zhonglin Group, carries out Zhonglin pallet leasing business based on the Group’s development strategy, combining the Group’s resources and the advantages of Fuzhou Guolin Putian Industrial Park, gradually expanding from the southeast coast to the whole country, and cooperating with Zhonglin system enterprises to establish a nationwide service network.

The pallet industry maintains a high growth rate and the steady development of enterprises is inseparable from the support of capital. Multi-level capital market can provide enterprises with diversified financing channels and help them obtain quick financial support, thus facilitating their expansion of production, strengthening technology research and development and product innovation. in September 2022, Prato Technology held an IPO kick-off meeting, firing the first shot of the company’s official launch of capital strategy. In the future, Plato will continue to consolidate and enhance its leading position in the field of pallet recycling and sharing, build a continuous development and innovation system, continuously collaborate with industry changes, continuously upgrade its products and services, and help promote the development of digital intelligent logistics.

10

Implementation of lean to promote enterprise management level

With the development of the times, the management style of pallet enterprises has gradually transitioned from rough management to scale enterprise management slowly and then to lean management. For example, Jiangsu Zhonghe Intelligent Packaging takes the lead in adopting JIT, TPS and IOT management of production process, which not only effectively ensures the stability of product quality, but also reduces labor cost and improves production capacity. Zhejiang Kaihua continues to promote and optimize the KMS lean management system, striving to achieve the “seven zeros” goal of zero switching waste, zero inventory, zero waste, zero defect, zero failure, zero stagnation, zero accidents, and achieve excellence.

Second, 2023 China pallet market development outlook

The year 2023 is the opening year of the comprehensive implementation of the spirit of the 20th Party Congress, the key year of the 14th Five-Year Plan, and the first year after the optimization and adjustment of the epidemic prevention and control policy. Although facing multiple shocks and challenges in 2022, affected by many uncertainties and unexpected changes, China’s economy still shows strong resilience and generally maintains a growth trend, which provides good market conditions for the development of the pallet industry and drives the growth of pallet market demand, and the development of the global market will also bring new momentum to the pallet industry. We should see that the healthy and orderly development of the whole pallet industry chain is of great significance to promote the modernization of China’s supply chain system, the integration and integration of trade and commerce circulation, and the high-quality transformation of the logistics industry to a safe, stable, efficient and green. Pallet enterprises should seize the opportunity to realize the transformation from big to strong, and make efforts to promote the high-quality development of the pallet industry in four aspects: standardization, sharing, wisdom and greening.

01

The use scenario is getting more and more mature, and pallet recycling is entering a new stage

Over the years, with the vigorous promotion of national policies on pallet recycling and transportation with boards, the steady promotion of enterprises focusing on the “double carbon” target and the concept of green development, and the orderly implementation of the “Belt and Road” pallet sharing action (BRAPS), the pallet recycling and sharing is moving to a high-speed development stage. Recycling is progressing rapidly towards a high-speed development stage. In the future, we should further deepen the concept of pallet recycling, open up the pallet recycling between logistics hub nodes and various industries, and enterprises will also increase the development and investment of pallet recycling business, actively show the pallet sharing mode based on various new technologies, play the role of the “Belt and Road” pallet sharing action mechanism, and carry out This will definitely set off a new wave of pallet recycling system with Chinese characteristics, and thus better promote the cost reduction and efficiency of the supply chain.

02

Diversified drive of the industry and society, with the opportunity of pallet transportation

With the innovative development of supply chain, the huge demand for pallets will be released, and more pallets will “come out” of warehouses and logistics parks to play an active role in the supply chain. With the increase of standardization of freight models, the competition of logistics enterprises will change from single-vehicle capacity to improving the efficiency of cargo turnover, and the use of pallets is the most effective tool to realize rapid loading and unloading; the rising labor cost, the serious aging of labor force, and the gradual iteration of labor resources for heavy work, there is an urgent need for automation, intelligence and mechanization to replace manual labor, and pallets are indispensable as the basis of cargo movement. The unit is indispensable; the development of digitalization and intelligence, the arrival of the era of unmanned logistics is bound to require the unitization of goods. China is already on the eve of the era of great development of transport with plates, the application of pallets will run through the entire supply chain, pallets into the car, pallets into the box, along the “Belt and Road” to West Asia, to Central Asia, to the European Union, to South America and other directions to expand, cross-country use, in order to improve the efficiency of the supply chain, better show the application of the collection of pallets.

03

Optimization and upgrading of digital pallets and full penetration of intelligent services

The new round of technological revolution requires accelerating the technological innovation and industry upgrade of modern logistics, and accelerating the digital empowerment of modern logistics. In the future, the digitalization of pallets will be generally promoted, and intelligent and digitalized pallets will be more popularly used in logistics and supply chain. Pallet companies will continue to improve their digital service capabilities in the supply chain, so that pallets will not only be used as unitary logistics apparatus for carrying goods, but also for the management of goods and pallets and monitoring of goods in transit, realizing digital drive and collaborative sharing. Pallet equipment enterprises will also increase the innovation and development of automatic and intelligent equipment, constantly optimize product design, improve product quality, performance and competitiveness, enhance the comprehensive strength of enterprises, provide overall solutions for the industry, and strive to cultivate a number of internationally competitive manufacturing enterprises, follow the “Made in China” to go out and better serve the global market. to better serve the global market.

04

“Double carbon” target requirements are clear, green development is imperative

Green innovation is conducive to the conservation of resources and protection of the environment, but also in line with the new requirements of green development, the concept of green environmental protection throughout the development chain of the pallet industry, to enhance the sustainable development of the pallet industry. Promote green innovation in the pallet industry, vigorously develop green technology, promote the use of green and sustainable raw materials, improve the recycling rate of resources and waste, and effectively achieve green and sustainable development of society. The application of green new material pallet not only expands the use scene and application scope of the pallet, but also makes a contribution to environmental protection. Therefore, improving the research and development capability of lightweight and green new materials and expanding the scale production and application of lightweight and green new materials is an important direction for the future development of the pallet industry.